PROJECT VENUE

Venue 466

is a function and conference venue located in Kameeldrift East, Pretoria.

THE PROBLEM

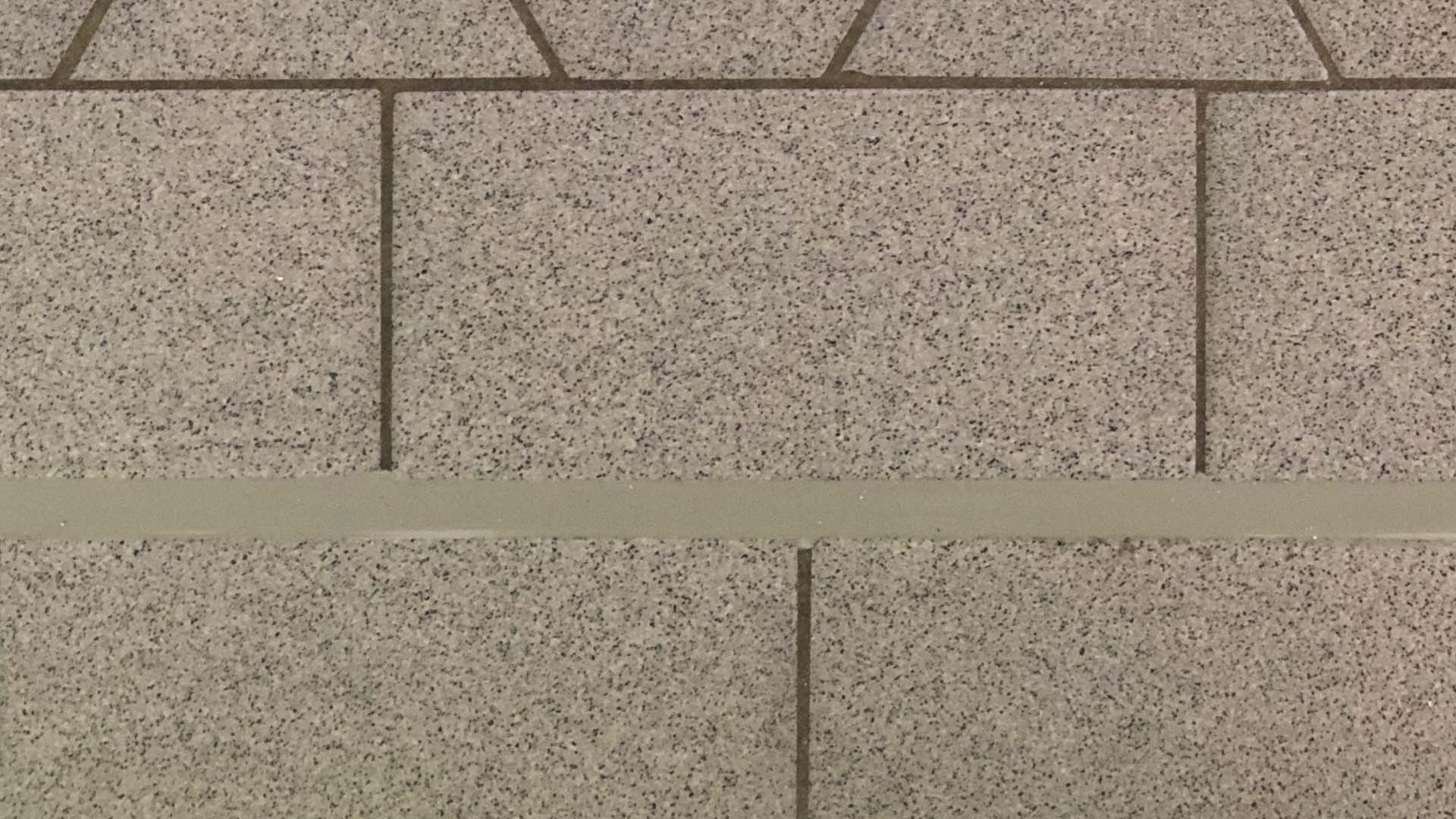

The project area is a terrace of approximately 121sqm covered with an epoxy coating that offered very little slip resistance. Having been applied approximately three years earlier, the delaminating coating did not make for a good first impression. In addition, an old-style floor drain presented a trip hazard and the falls of the floor meant that during heavy rains water would run into the venue causing damage to property.

OUR SOLUTION

We recommended resolving the lack of slip-resistance by removing the epoxy coating to take advantage of the higher slip resistance coefficient offered by the exposed concrete. By treating the surface with Becosan’s non-film forming treatment

unsightly delaminating floors will be a thing of the past, and opting for a polished concrete finish means the client will have a hard wearing, good looking floor with a projected lifespan of more than two decades.

The client was invited to choose their preferred aggregate exposure ranging from a cream finish to full aggregate exposure, and a floor finish from our Matt-Plus, Semi-Gloss and High-Gloss options. In this instance our client opted for full aggregate exposure with a Matt-Plus finish.

To address the problem of water flowing into the conference hall, we advised excavating the existing drain system and replacing it with a new effluent line, channel- and floor drain. We recommended replacing an ill-placed fall in front of the sliding door with a channel drain. As the channel drain is situated right at the hall entrance, we recommended a custom heel-safe, stainless steel drain cover be installed.

GETTING TO WORK

We started by demolishing and excavating the existing 25m-long effluent drain system, stripping the epoxy coating and grinding the floor to achieve the desired aggregate exposure. Next we installed a new drain system comprising a custom channel drain linked to a floor drain and effluent pipeline. The new drain was set in place with high strength concrete with aggregates to match the existing floor. The concrete was left to cure for 28 days, ensuring that it achieved the appropriate strength before applying the Becosan polishing system. Finally, isolation joints were cut in the newly placed concrete to accommodate any slab movement and in order to ensure a level surface, the joints were filled with a semi-rigid joint mix.

WHAT THE CLIENT HAD TO SAY

“While I am pleased that the risk of patrons slipping on the terrace has been taken care of, I was really impressed with the attention that was paid to the detail of ensuring that there is consistency in the aggregate exposure across the entire floor, even in the corners.”

- EY Stuart, Owner of Venue 466

Congratulations to our Craft Flooring projects team for a job well executed. By addressing each one of the client’s needs, the facility now boasts a beautiful non-slip, low maintenance concrete floor that will not delaminate.

When repairing and installing floor joints without the guidance of architectural specifications or engineering drawings it may be tempting to disregard the need for proper joint care. However, not preparing the joints for the stresses it has to endure is a penny-wise pound-foolish approach that will almost surely result in floor failure.

Commercial and manufacturing facilities understand the need for a well-designed, hygienic, durable, adaptable, cleanable, and serviceable drain system. Working closely with the engineering and production teams we can design a suitable full-service drain solution, commission the manufacture thereof, and then install the system in line with the specified requirements.